[T]o continue churning out delicious coffee, brewing equipment requires regular upkeep—that’s a given. Some cafés fix their espresso machines and batch brewers themselves, others go to local independent technicians, and a number rely on their roasting company to resolve mechanical issues. With the establishment of the Specialty Coffee Association’s (SCA) Coffee Technicians Guild, coffee equipment service is receiving more attention and consideration in the specialty coffee industry, and for good reason: healthy equipment is probably the most vital component of a successful café, after coffee and water. It’s the perfect time to ask yourself, “Are we offering brewing equipment service in a way that optimizes benefits for both our company and our customers?”

Size & Service

Roasting companies range in size from small, local one-man shows to large-scale companies operating coast to coast. Size is a critical factor when considering adding an internal service tech department—around 200 to 250 local accounts seems to be the tipping point, according to Terry Patano, owner of DOMA Coffee Roasting Company in Post Falls, Idaho. Running a small roastery, Patano discovered that paying an in-house technician meant the tech had to multi-task in other departments, which negatively impacted customer service and prevented the tech from focusing on cultivating specialized skills.

Nossa Familia Coffee in Portland, Oregon, maintains equipment at about fifty local wholesale accounts in addition to their own espresso bar. They used to have a service department, but decided to close it and contract with a local tech company.

“It is a very specialized thing,” says Geoff LeCoq, Nossa Familia’s operations manager. “The level of service we were getting from our in-house tech couldn’t match the third-party companies, who exclusively maintain equipment and have that knowledge.” They can now offer twenty-four-hour access to quality service and machine maintenance. Nossa Familia’s wholesale accounts get added value from the arrangement—minor issues can still be handled in-house and the third-party contract means subsidized service fees.

Gimme! Coffee, based in Ithaca, New York, established their service department almost immediately after opening ten years ago. According to Thom Cooper, Gimme Coffee’s equipment and facilities manager, it was highly beneficial, because “anything we needed done was done almost immediately. We didn’t have to wait for a technician to come.” They now have seven cafés, supply a long list of wholesale accounts in the surrounding areas, and roast an average of 230,000 pounds of coffee per year.

Control & Quality

Shad Baiz, chairman of the newly formed Coffee Technicians Guild, says having control of your customer experience is where roasters get the most benefit out of having an in-house technician. He explains that a tech who is invested in the company, knows its coffee profiles, and builds history with clients also improves the quality and consistency of the coffee.

The key lies in identifying and hiring the right person.

A service tech will most likely have more face time with clients than anyone else within a roasting company. Finding the right person—with a combination of people skills and technical know-how—can heavily influence the decision to hire or outsource a technician. Independence, logic, critical thinking, and a customer service mindset are among the traits a technician should have and develop.

Alex Lambert, part owner of Black Rabbit Service Co. in Portland, says every tech should possess, “above all, customer service. I can teach the wrenching and technical knowledge parts, but it is much harder to teach someone how to interact with a customer.”

Ryan Klineman, who teaches “wrenching and technical knowledge” at Nuova Simonelli, agrees with Lambert. He tells each of his students, “You guys need to create a positive impact, because the coffee industry needs professional, honest, hard-working, and gifted people with your skill set.”

Equipping for A Growing Future

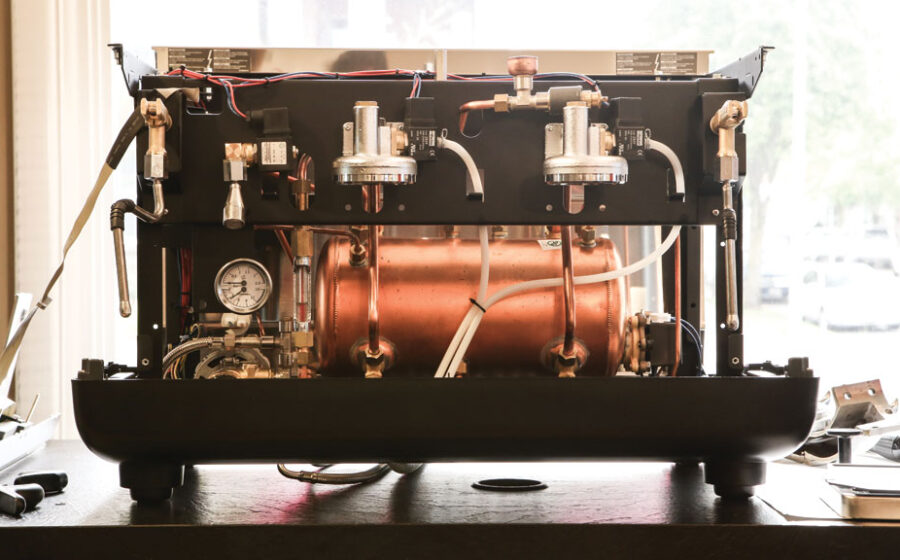

Adding a service department demands extensive planning and education. Techs can seriously injure themselves simply by touching the wrong wire inside an espresso machine. Comprehensive training is fundamental to providing dedicated service to a roaster’s accounts—whether done in-house or through a third-party service. Equipment manufacturing companies make it easy for roasters, third-party contractors, and independent companies to receive training through hands-on classes, official online technical specs and information (like Bunn’s Online Learning Center), and tech support phone lines (like at La Marzocco USA). Information is accessible to technicians, café owners, roasters, sales people—anyone interested in expanding their knowledge.

In addition, the Coffee Technician’s Guild aims to support manufacturers by offering technical foundational training in core competencies such as electrical, plumbing, and filtration, laying the groundwork for more concise and company-specific education. Ideally, this will open more opportunities for technicians, allow independent service companies to train more cost-effectively, and give technician-seeking roasters more hiring confidence.

The question of whether to develop an in-house equipment maintenance team or to hire an outside company can’t be decided by any one factor. Customer service, technical skill, cost, efficiency, and safety must all be taken into consideration when devising the best service plan for your business. Pursue a path that gives your customers the best product, served by baristas who have confidence in their well-oiled (and well-maintained) coffee equipment.

—S. Michal Bennett is a poet, blogger, and freelance writer. She and her husband co-own Coffee Roboto in Coeur d’Alene, Idaho.