The Roastery Breakdown series is presented by our partner, Loring.

Think back to the last time that you took a sip of coffee that made you pause—a sip so shockingly delicious and distinct that you felt like you were tasting coffee for the first time. That’s the experience that Christian Forrer, founder of ViCAFE in Zurich, Switzerland, wanted not just to capture once but to replicate: to offer a transformative experience with every cup, one that would give customers a renewed sense of appreciation for what they were drinking.

Forrer grew up in Eglisau, a small town in northern Switzerland. Eglisau is perhaps best known as the hometown of Vivi Kola, a historic Swiss soda brand founded in 1938. According to Pascal Herzog, ViCAFE’s COO and head of impact, Vivi Kola used to hand out free sodas to schoolkids on Wednesdays, which shows the “emotional connection” the brand has to the town—especially for people like Forrer who grew up there. But by 1986, it had ceased production.

ViCAFE’s story is intimately bound up in the soda brand’s: It was founded in 2010 when Forrer decided to revive Vivi Kola. Herzog says that Forrer wanted to recreate “this positive experience that he had as a child growing up.” His revitalization project was immediately successful: He sold 2,500 bottles of Vivi Kola out of a small cafe, called ViCAFE, within the first two hours of the brand’s relaunch.

Still, anticipating that customers might not regularly stop by just for cola, Forrer bought a small coffee roaster for the Eglisau shop. In 2014, he opened the first ViCAFE Espresso Bar in Zurich.

Now, ViCAFE has 17 retail locations across Switzerland, in locales like Basel, Eglisau, and Zurich. Herzog says the roastery plans to open two new cafes in 2025. Aiding that pace of expansion is the fact that many of ViCAFE’s locations are small. “Most of them are a takeaway concept, like a window-in-a-wall concept,” says Herzog.

After outgrowing its old roasting space, ViCAFE moved in November 2023 into its current headquarters: an old train station in Zurich. The move allowed the company to expand its roasting capacity, automate much of its facility, and house most of its daily operations under one roof (the Vivi Kola bottling plant remains in Eglisau).

Herzog recalls how limited the former roasting space was: “We basically had an office in one place, then we used an old railway canteen to do the baking, and then the roasting was in a third place,” he says.

By contrast, the new space is big enough for ViCAFE to bake pastries for the cafes and roast coffee for its cafes and online store; it also operates a cafe on site. The train station functions as a large business hub, and ViCAFE shares space with a brewery, a chocolate maker, and a soap manufacturer.

The move hasn’t just allowed ViCAFE to automate its roasting operations, but to connect it to the larger Zurich community.“It’s quite nice, not only that everyone from [Vi]Collective is under one roof, but that we are also part of a greater community,” Herzog says.

Quick Facts:

Location: Zurich, Switzerland

Footprint: 1,500 square meters, including the roasting space, office, and cafe

Capacity: 180 tons (360,000 pounds) in 2024, projected to hit 210 tons in 2025

Retail and/or wholesale roasting: Both

Large-Scale Roasting

ViCAFE roasts 180 tons of green coffee a year on its Loring S70 roaster, exclusively for the Swiss market. Herzog says that while there is space for a second roaster, the S70 serves the roastery well for now.

Seventeen cafes seems like a hefty number of shops to supply, but Herzog explains that most locations can be stocked by one delivery driver making two tours around Zurich, one in the morning and one before lunch. “We have our own bakery, so we need to start the first tour normally at 5 o’clock with all the baked goods and some beans for coffee shops that need them.” He points out that Switzerland is small, so driving to many of ViCAFE’s locations is akin to a quick trip to the suburbs.

Most of the company’s green coffee, however, is stored in Basel, 70 miles away from Zurich off the Rhine River. “Every Monday, the truck drives to Basel, and then gets the beans that we need for basically the week or two weeks,” says Herzog.

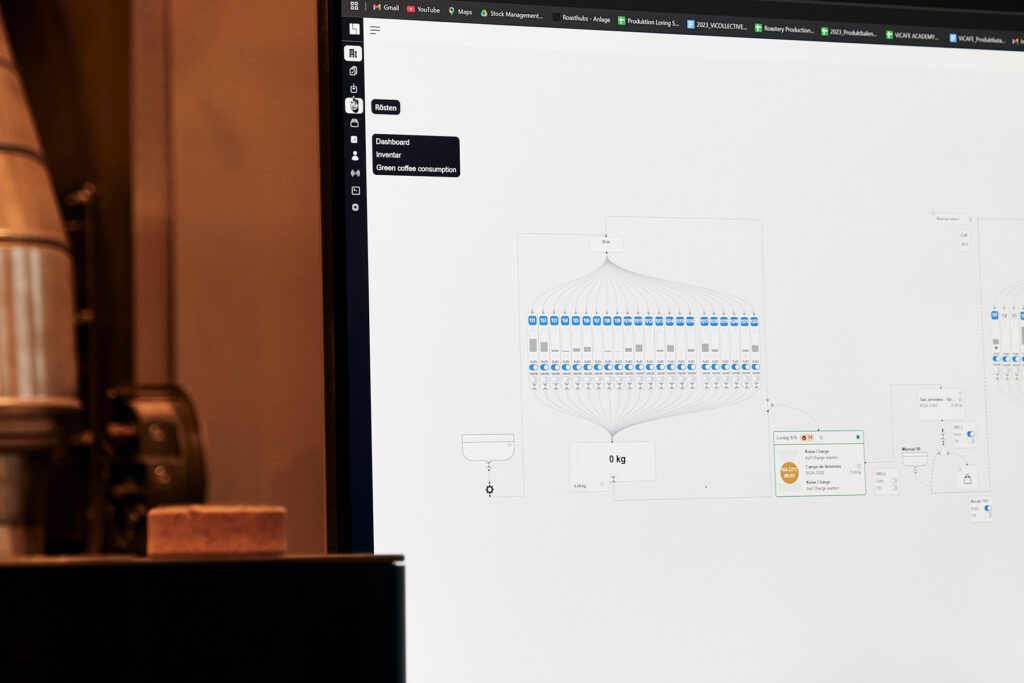

Once the coffee gets to the roastery, ViCAFE’s unique roasting model really shines: Nearly every step is automated, and every piece of equipment connected through powerful software. Green coffee is loaded into the roaster and is then roasted according to a roast plan; next, it goes through a destoner and is sent to a large coffee silo to rest—all with the press of a button. The coffee is then sent via conveyor belt to be packed in bags, organized, and sent out by the fulfillment team.

Herzog notes that this is a pretty typical workflow, but what makes ViCAFE special is the integration of its software so all parts of production are talking to each other. “What is crucial is that we have the full software integration … [we have] a fully integrated workflow with a software that talks to each and every machine,” he says. “Automation is very much about the software, and less about the machines themselves.”

The automation process starts with a plan. “The head roaster, he does the planning,” Herzog says. “Every morning, at 7 o’clock, they create a roast plan, which is then entered into the software. They do a packaging plan which is also entered into the software.”

On longer roasting days—10-hour days with two people working—the roastery can turn over more than two tons of coffee. On half days, it can produce up to 1.4 tons.

While automation is often dismissed or seen as counter to the idea of hand-crafted coffee, Herzog believes that “there is no contradiction between automation and making a high-quality product where [the roaster can] pay attention to each and every detail.” He says that automated processes help the team focus their attention on quality control and keeping standards high.

Still, “It did take some time to get used to the idea of automating as much as possible, and to have a more in-depth understanding of machinery and how those machines work and what we need to do,” Herzog says.

He acknowledges that ViCAFE’s starting point as a cola company and bottling factory made the idea of automation more plausible, even though the bottling plant isn’t integrated in the same way as the roastery. “We have 24 machines [at the bottling factory that are] basically fully synchronized,” Herzog says. “And we have people, for example, working in maintenance over there, which can help us also to transfer some of the knowledge and experience.”

Still, maintaining a personal touch remains important for the roastery. “We really try to only buy coffee from coffee farmers and farms that we have visited and met personally,” Herzog says.

That ethos has extended outward to how ViCAFE thinks about other products, like milk. “We have started, with other roasting companies, a cooperative a couple of years ago to produce the first organic oat milk in Switzerland,” Herzog says. “The idea was that we put so much effort into sourcing trips and visiting farmers and have these collaborations, but at the same time, we buy oat milk with random oats.” ViCAFE also became a B-Corp-certified business and tries to apply its sourcing model to “different aspects when it comes to the value chain.”

Equipment Breakdown

Roasthubs automation software: ViCAFE is able to automate and connect its machinery through software designed by the Belgium-based Roasthubs. Prior to the software, Herzog says they “had an Excel-based system before, but again, lots of manual work you need to do, lots of human errors, as well as people just forget or they don’t do things properly. And [with] this, it became much easier.”

The software allows Herzog and the team to visually track where coffee is moving and set the queue for each day’s roast. If you wanted to see how full the silos are, for example, you could look at the software to determine which compartments are full and which are empty.

The roasting software allows for traceability down to every bag of coffee. “I can click on a roast log number and then you see each and every green parcel that went into this roast number,” Herzog says. “If you want to be a professional player in wholesale, for example, and you can’t offer those guys full traceability, all back to a single coffee bag, then you’re in a very difficult position.”

This system also allows ViCAFE to keep roasting operations lean—on the day we spoke to Herzog, three people were working in the roastery doing the entire day’s worth of fulfillment, packaging, and roasting. “With the few people that we have, we can hopefully give them jobs and professional challenges that are interesting and that make them grow in the coffee space,” says Herzog.

Roasted coffee silo: ViCAFE stores roasted coffee in a large silo, which allows the coffees to rest before being packaged. Afterwards, they travel via a conveyor belt into the silo.

“It’s one big silo, but it has 16 compartments,” says Herzog. “We can block certain cells for certain qualities. So for example, for decaf, we have a blocked cell only for decaf coffee to avoid any mix-up.” The coffee travels through tubes that connect the destoner to the silo, which are located under the floor between the railway tracks of the building.

Packaging: Coffee then travels from the silo to a carousal packaging machine made by a company based in Bologna, Italy, to pack retail bags.

“Every parcel that you prepare for the online shop or for your espresso bar … somebody needs to prepare a parcel,” says Herzog. “Somebody needs to prepare a delivery for an espresso bar. So you can automate your roasting, you can automate your packaging, but in the end, you need a lot of space to do your fulfillment.”

A Worthwhile Learning Curve

Herzog says that learning all the new systems and machinery was a challenge. “It was a steep learning curve earlier this year, and my confidence level is much, much higher now than if you would have talked half a year ago,” he says.

But he also sees the team growing around him. “They are solving problems themselves, and hopefully we also give them the trust and the knowledge … that they are in a position to confidently take decisions and make it happen,” he says.

Before this new system, Herzog says the roastery’s team members worked in much more strictly defined roles. “I think what we changed as well … [is that] every person was very much on their little job. One person doing fulfillment, another one preparing pouches, and the third doing roasting. And now we work more in teams, so we move around with the team in the roastery.”

In the end, he says, automation is a powerful tool, but it still relies on people—and the tools of the roastery can only run if workers feel empowered and supported. “Yeah, the tool is the software,” he says. “But the people are, in the end, the success factor number one.”

Ashley Rodriguez assisted in reporting this story.