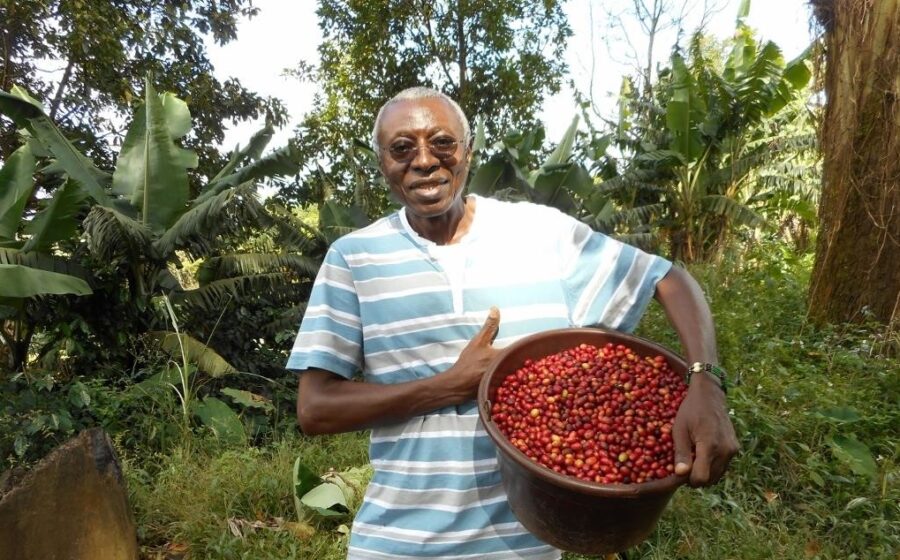

[E]arlier in the year, Matti Foncha arrived in Portland with three large bags. Two of them were filled with coffee samples and a couple ziplock bags of fragrant cascara from his farm, the Alongsi Estate, in one of Africa’s most unexpected coffee countries, Cameroon. Over the next few days, Foncha, a tall, thin man with short-cropped white hair, led a marathon sample roasting, cupping, and visitation schedule before departing for home to incorporate the feedback he received into the current harvest. (My husband and I helped organize this trip and worked with Foncha on grading standards.) A few months from now, the first container of Cameroonian specialty coffee will be sent to Portland, with another heading to Vancouver and another to Phoenix. He’s been importing about a container a year for years, and this increase in production is the result of many long-term quality plans and relationships built with the farmers, as well as roasters on the receiving end.

It’s an exciting time for Foncha, founder of Cameroon Boyo, and his farmer partners, but it’s been a long time coming. While coffee has been grown in Cameroon for years, because of topography and the infrastructure left from colonial times, farmers never had central processing mills. Each farmer did his or her own harvesting, pulping, fermenting, washing, and drying, and the best quality was often dried on mats on the ground. Historically, Cameroonian coffee was bought in large quantities at very low prices for commodity-level blends. Foncha is changing that.

While coffee has been grown in Cameroon for years, because of topography and the infrastructure left from colonial times, farmers never had central processing mills.

“About twenty years ago, I left the corporate world to work with coffee and it became clear that we had to build our own processes from scratch,” says the Oxford-educated engineer. “It took us a long time of working with the same farmers year after year and building relationships to get our quality volume up to one container.” He adds that a main focus for him has been communicating to the farmers that ‘we are all in there together’ … this is not another government or NGO sponsored initiative. The leadership I bring is from my own goodwill and knowledge that I cannot build good market capacity by myself, so those who want to perform to the standards we set will reap the rewards.”

He has developed a model he calls “circles of excellence,” in which farmers organize into small clusters of fewer than twenty, are advanced the money to build a micro-processing station, and hold each other to the quality standards required for entry into the circles. “Every evening, the day’s coffee harvest comes to the washing station, which is walking distance from each farm. The other farmers have to accept it as holding up to the group standards, all unripes are removed, and that farmer’s weight is registered before the coffee is all processed together,” says Foncha. The micro-stations have been designed with a prototype in demonstration now. Twelve groups of farmers have qualified to be in circles of excellence, waiting only for certification, and the prototype is functioning without a hiccup now. Foncha expects to build five more washing stations this year, each of which has a four-ton capacity yearly. The washing stations provide a rare opportunity for outside investment—a coffee roaster who funded the building of one could expect first refusal of coffees processed through it, for example.

Foncha has developed a model he calls “circles of excellence,” in which farmers organize into small clusters of fewer than twenty.

For years, Foncha has been holding small experiments on his family’s coffee farm, the Alongsi Estate, which is near Nkwen, and the coffees he brought to Portland and London were largely from those experimental micro lots. “I like to do my own experiments, see roaster’s reactions, and then if they like it, pick one or two farmers to do the same processing methods under my supervision.” These experiments include pulp natural and full natural processing, varied fermentation times, and recently identifying a potential spontaneous typica mutation that turns yellow, not red, when ripening and separating the micro lot. (Foncha is working with a biologist to determine the nature of these plants: could be, he’s identified the first Cameroon-specific coffee variety!)

Mark Cameroon specialty coffee in your minds. You’ll be hearing a lot more about it in years to come, largely due to the tireless work and unavoidable grace of Matti Foncha, the tall grandfather who is single-handedly revolutionizing his country’s coffee industry.

—Emily McIntyre is a regular contributor to Fresh Cup. She and her husband founded Catalyst Coffee Consulting.