The Roastery Breakdown series is presented by our partner, Loring.

In 2003, Bob and Carmen Garver founded Wicked Joe Organic Coffees in Topsham, Maine. Their goal was creating a coffee company that emphasized both sustainability and community. Those are easy words to throw around (especially in the coffee industry, where they’ve become well-worn clichés), but the Wicked Joe team knows just how hard it is to actually maintain those values—especially as a company grows.

Bob Garver began his coffee journey while he was in the army, stationed in Turkey. According to John Rohn, Wicked Joe’s chief operating officer and integrator, Garver enjoyed “a lot of time out in the community and coffee, as a ritual, was a big part of his experience there.”

Upon returning to his hometown of Santa Cruz, California, Garver started a coffee company that he ran for 10 years. When he and his wife Carmen had kids, they decided to move closer to family on the East Coast, and that’s where they established Wicked Joe.

Over the last 20 years, Wicked Joe has grown to inhabit a three-building campus. It roasts coffee for wholesale clients and local cafes, and is stocked in more than 8,000 grocery stores across the nation, including Publix and Sprouts.

All along the way, even amidst that growth, the company has stayed true to its founding ethos.. Sustainability has “always been front and center” with how Wicked Joe operates, as Rohn puts it.

Sustainability on a Large Scale

Wicked Joe roasts coffee on a large scale—last year, its output totaled 2 million pounds—so to meet its sustainability goals, the team needs an all-encompassing approach. That means using solar technology for power and heating throughout the campus. For example, the roastery has a solar array—a collection of solar panels that generate electricity—that offsets power needs in its tea production space and headquarters building during peak times.

“Being up here in Maine, one of our largest expenses and consumers of natural gas would be heating that building, and so [solar] offsets the heating requirements,” says Rohn.

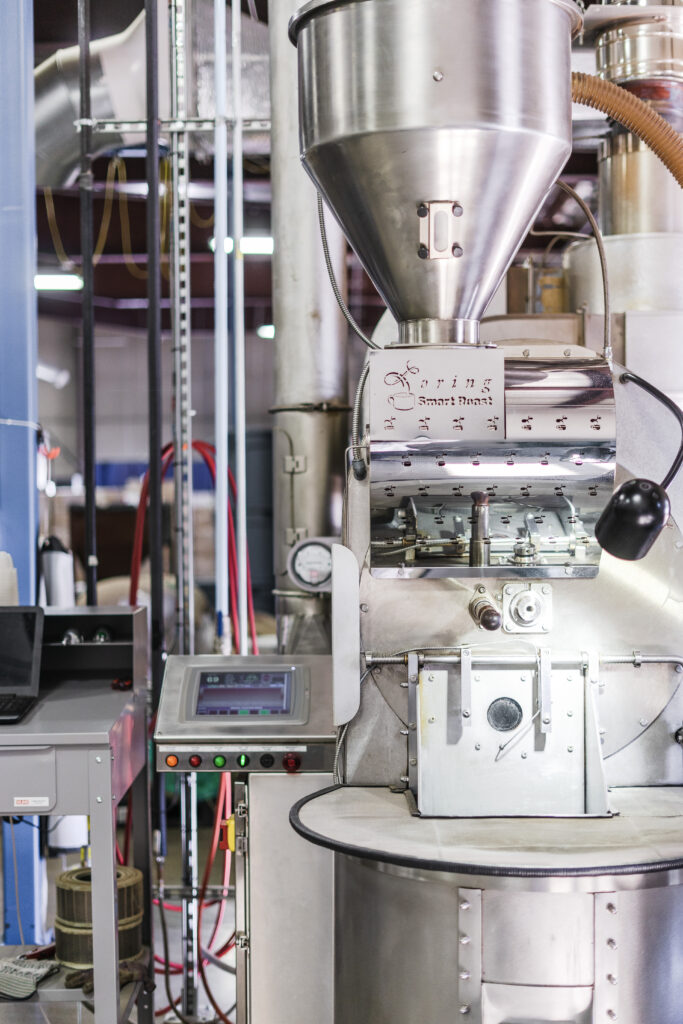

Wicked Joe’s commitment to sustainability also dictates its choice of roasting equipment. The roasting facility currently has three S70 Peregrine Loring roasters and one S35 Kestrel, which it uses for the bulk of its production. (It additionally uses a S7 Nighthawk for roasts in development or limited microlot coffees.)

Many coffee companies choose Loring because of its roasters’ energy efficiency. Before they made the jump, the team at Wicked Joe decided to perform their own in-house tests to see if the machines aligned with their sustainability goals. “The claim is that they use 80% less fossil fuels,” says Rohn. “We did some studies early on and that seemed to line up.”

While many traditional roasters require natural gas to power the roaster and afterburners, Rohn notes that Loring machines have an enclosed smoke system that burns off smoke during the roast and doesn’t require an afterburner. He says these features have been a “tremendous advantage when it comes to reducing our natural gas consumption.”

Fast Facts

Roastery location: Topsham, Maine

Roasting capacity: 2 million pounds per year

Retail and/or wholesale roasting: Both

Equipment Breakdown

Coffee silos: In a past Roastery Breakdown article, we profiled ViCAFE in Switzerland, which uses a silo to store roasted coffee. Wicked Joe also uses coffee silos, but for storing green coffee instead.

“We have 10 large silos and a couple split-bin smaller ones that hold 10,000 pounds of coffee,” Rohn says. Once a pallet of green coffee bags arrives at the roastery, the coffee goes through different cleaning mechanisms and destoners before being loaded into its assigned silo.

The silos are equipped with technology that lets the roasting team track the quantity of coffee down to the pound. “So, we know how much coffee we put in there, we know how much coffee is in there at any given time, and we can weigh the coffee coming back out,” Rohn explains

Similar to ViCAFE, Wicked Joe’s silo system connects directly to its Loring roasters. “We set the production schedule for the day,” says Rohn. “The silo system will deliver [the correct coffees] to a hopper above each roaster … in the correct proportions for our pre-roast blends. When the operator at the roaster is ready, they basically just have to push a button.” The silo then prepares to deliver the next coffee in the queue to be roasted.

A coffee silo system is a considerable investment for any roastery, no matter the size. Before silos, Wicked Joe used an overhead crane system similar to one that Garver saw in a granite facility. But as the roastery grew, avoiding injuries—including from repetitive strain or accidents—became a major concern. The management team realized they needed to upgrade to a system that offered improved efficiency and enhanced workplace safety.

“We … knew that the crane system was preventing us from hiring the best people, and restricting us to hiring the strong people that could maneuver those sacks all day,” says Rohn.

JACKY Bins: While most roasteries use 32-gallon plastic bins for storing coffee, Wicked Joe needed a larger alternative for its most popular coffees. It found a perfect solution with JACKY Bins. These white bins are on wheels, and hold roughly 600 pounds of coffee. They can be wheeled around the roastery as well as lifted into its silo system, or used when packaging roasted coffee.

According to Rohn, the JACKY Bins “can replace basically 10 buckets with one bin. We have two departments in particular where we do enough volume that we can roll over multiple JACKY Bins.”

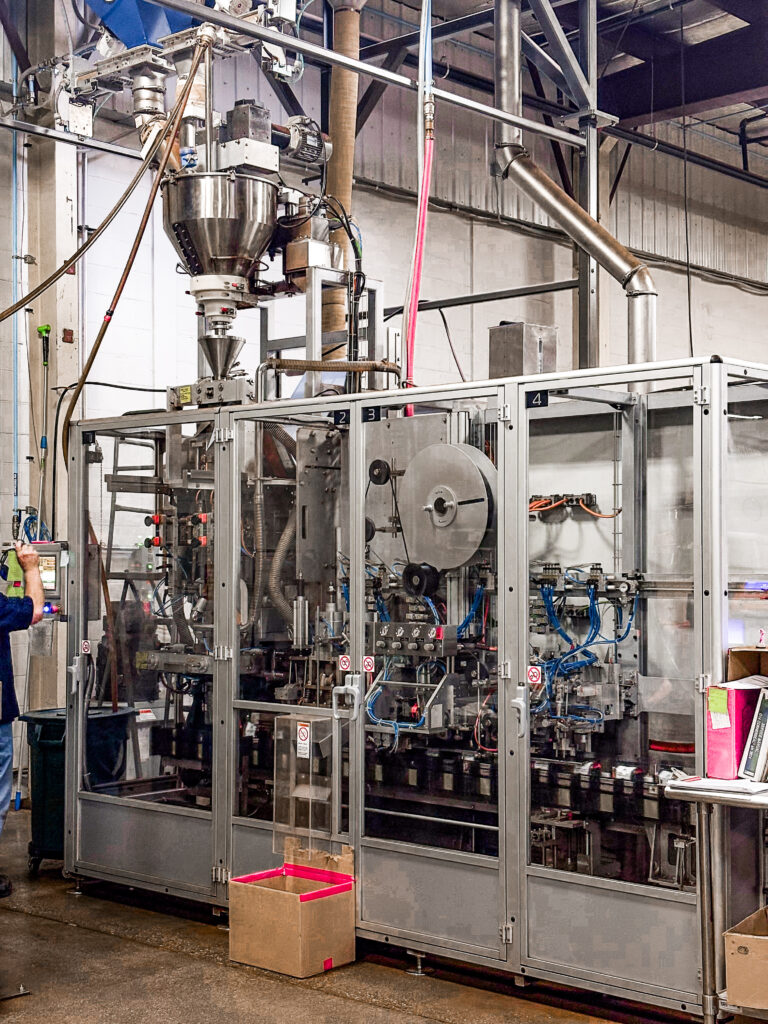

Fres-co Machine: Instead of purchasing blank bags, labeling them, and filling them with coffee, Wicked Joe uses a Fres-co Machine that builds bags from giant rolls of packaging material, then loads the coffee inside before sealing.

The coffee bags pop out ready to be sold. “It takes three people [to operate the Fres-co], but … a team of three over there might be able to do a few hundred cases,” Rohn says. That makes the Fres-co “orders of magnitude … more efficient” than filling retail bags manually.

Real Connection From Origin to Roastery

Sourcing coffee for a large company is no easy endeavor, but Rohn is passionate about building relationships with people all along the supply chain. The way that the team accomplishes this is by giving care and attention not just to the farmers they work with, but to other actors along the way, like the people who import their coffee.

“There’s a lot of baselines that exist,” Rohn said, referring to working with and sourcing from the same people for 20 years. “They know what our expectations are, so we know that when we get something from them [or] if they want to recommend something to us, they aren’t going to recommend something to us that they know we’re not going to like. They already understand how we operate.”

Wicked Joe also maintains connections by regularly visiting its coffee partners. “We try to travel every year to origin,” says Rohn—in January, he visited coffee farms and co-ops in Honduras. “We don’t always get to go everywhere every year, but we try to make multiple origin trips to be present and check how things are going for them.”

Rohn says travel is key to understanding what farmers are going through. “It gives you a different level of insight into what’s happening, being on the ground versus what you are reading in the newspaper or online,” he says.

Maine might not be the first place that comes to mind when thinking about coffee hubs, but Wicked Joe proves that intentionality and a strong ethos are all you need to build a major coffee destination. More than 20 years ago, the Garvers set out to create a company that not only roasted great coffee, but which did what Rohn calls “a very California thing”—keeping sustainability at the forefront of its mission. Even as it’s grown into a large-scale company, Wicked Joe has used energy-saving technology to keep that mission alive.