This article is sponsored by our partner NitroBrew.

With a smooth texture and beer-like head, nitro cold brew continues to hit high notes with coffee drinkers worldwide. In fact, recent reports reveal nitro cold brew hitting a staggering 904% menu increase over the last four years.

Traditionally, serving nitro-infused drinks typically means investing in inefficient systems. Nitro setups can be cumbersome and generate waste, which may conflict with other environmentally-conscious business practices around the café, like composting spent grounds or reducing plastic usage.

We spoke to Murthy Tata, an inventor, chemical engineer, and founder of NitroBrew, to learn about the inefficiencies of serving nitro coffees and what cafe owners can do to eliminate the environmental costs of offering these drinks.

“The waste associated with nitro coffee is often considered ‘part of the process,’ but it doesn’t have to be,” says Tata. “And I think we have a lot to gain by rethinking what’s acceptable when it comes to how nitro drinks are prepared and served.”

At first glance, nitrogen gas might seem like a harmless ingredient used to make nitro-infused drinks. In general, nitrogen gas is sold in containers like liquid nitrogen dewars or steel cylinders that are refilled and reused repeatedly—that’s good, right?

The Hidden Cost of Nitrogen Gas

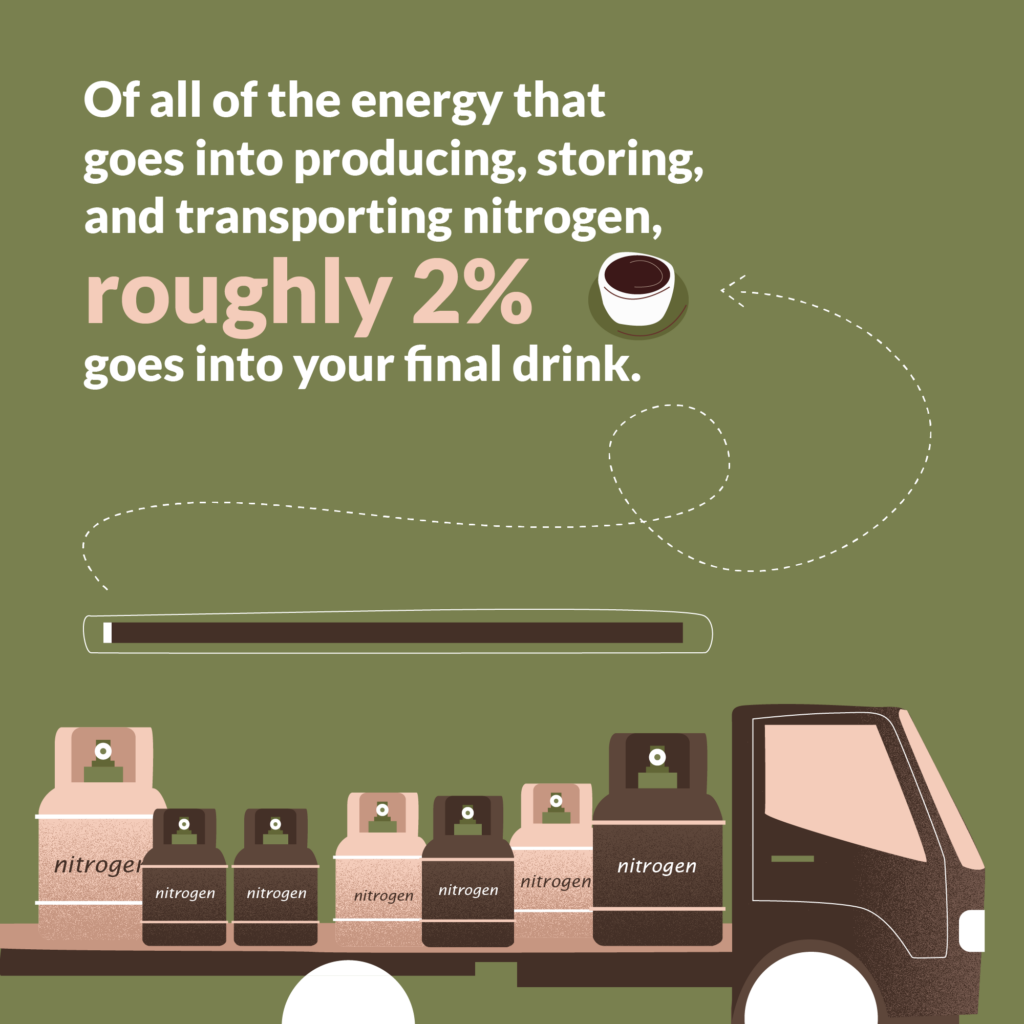

Unfortunately, the production, storage, and transportation costs involved in facilitating this movement of nitrogen for a cafe setting add up fast.

Gas Production — Air is roughly 78% nitrogen, but grabbing only nitrogen from the air is costly. Ambient air must be compressed and chilled, and the nitrogen separated in a dedicated production facility to produce nitrogen gas at 90% purity or higher.

“Compressing the gas to 3,000 pounds of pressure is very energy intensive,” Tata told us. “As well as separating the nitrogen.” The European Industrial Gas Association reports that 1,976 kilojoules of electricity are required to produce one kilogram (2.2 pounds) of nitrogen.

Gas Storage — Compressed nitrogen gas is typically stored in metal containers ranging from small, single-use cartridges to large commercial liquid nitrogen storage tanks at factories. The smaller the container, the fewer times it’s reused, with most single-use cartridges often going into landfills after one use—even though they are recyclable. Nitrogen concentrators that separate nitrogen from air to about 90% purity are an option. But they consume large quantities of air.

Gas Transportation — Last but not least, transporting containers of nitrogen gas around the country requires large amounts of fuel, and the carbon footprint is not trivial.

“A common scenario where we are in Arizona is that one truck can carry about one hundred cylinders of nitrogen gas for about one hundred miles,” Murthy explains. “If the truck is getting ~5 miles per gallon of fuel, that’s roughly 100 lb of carbon dioxide created per gas cylinder transported for a one-way trip. If you put that into coffee terms, that’s 0.1 lb of carbon dioxide waste created per gallon of coffee, which adds up over time.”

Nitrogen Consumed vs. Nitrogen Spent

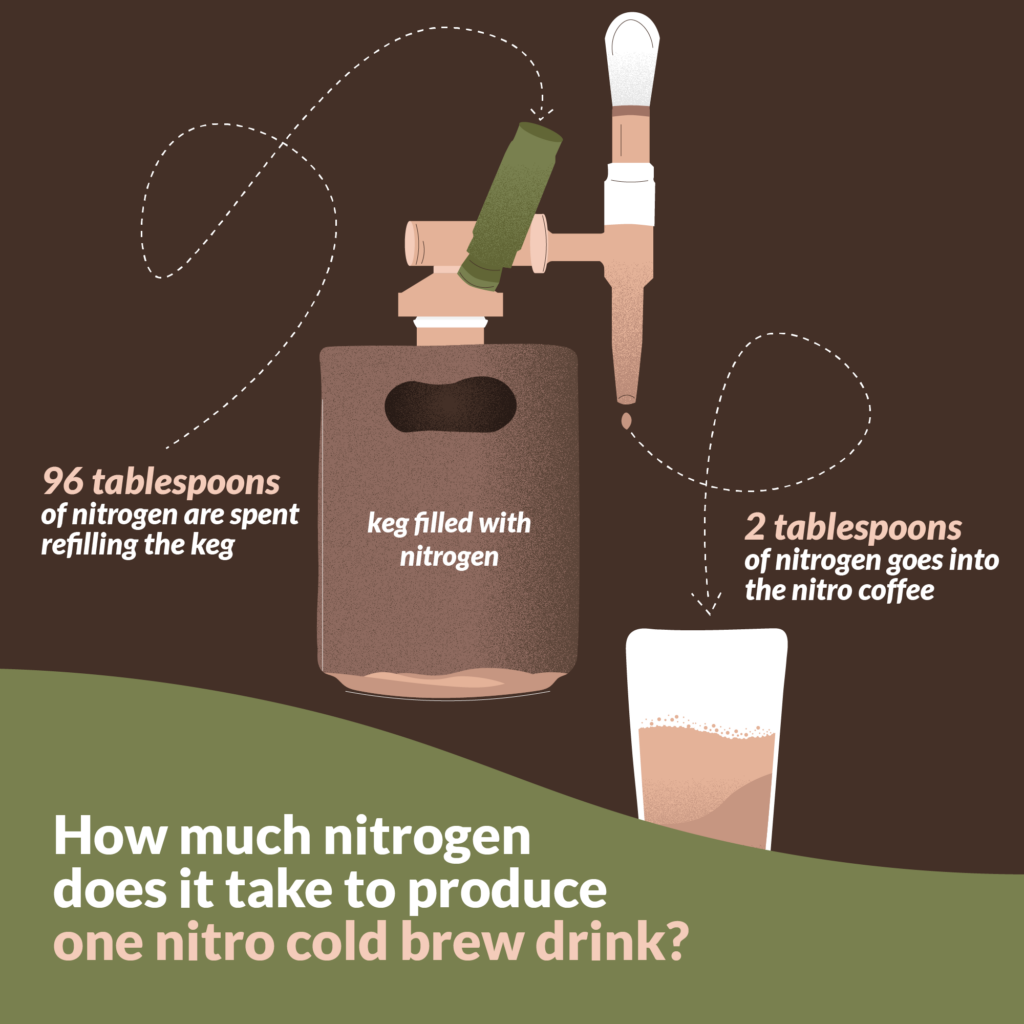

Most cafes serve nitro coffee through a keg filled at a roastery or brewing facility, distributed to the cafe, then attached to a dispensing station alongside a backup cylinder of nitrogen.

As the nitro coffee is dispensed from the keg, extra nitrogen gas is pumped back into the keg to preserve the 30 psi necessary to keep it pressurized. When the keg is empty with coffee, it’s really full of nitrogen gas that has been inserted back in there to keep the pressure up.

And this is where the math gets pretty wild.

“The average pint of nitro cold brew has a very small amount of nitrogen in it—roughly less than two tablespoons,” Murthy explains, “However, since you’re pumping nitrogen back into the keg while you’re dispensing coffee, you actually spend 96 tablespoons of nitrogen refilling the tank for every pint of nitro cold brew served.”

In other words, for every two tablespoons of nitrogen used to make a nitro-infused drink, about fifty tablespoons are “spent” refilling the keg.

“Of all the energy that goes into producing, storing, and transporting nitrogen, roughly 2% goes into your final drink,” Tata says. “Is it really worth all that?”

If Air is 78% Nitrogen, Should We Use That Instead?

Oxygen destroys drink quality over the course of a few hours. It’s why pure nitrogen is the best way to keep bottled and canned drinks tasting fresh—items that need to be preserved for weeks or months. But is pure nitrogen necessary if the end-consumer is enjoying a nitro coffee on the spot?

“I was working in the beer industry and theorized that, if we could infuse drinks with nitrogen at the time of service, we wouldn’t even need to deal with the nitrogen supply chain at all,” Murthy explains. “We could just use ambient air—it’s 78% nitrogen after all.”

Murthy brought his ideas to the coffee industry via NitroBrew’s Inline System. This commercial nitro-infusion setup allows cafes, coffee carts, and restaurants to infuse ambient air into coffee and other drinks. Users can infuse drinks with nitro to order without any complicated and wasteful keg systems.

“It’s a completely container-less way to do nitro coffee. No nitrogen production, storage, or transportation.” Tata says. “It happens right there when the customer orders.”

NitroBrew’s system still allows cafes to hook up traditional nitro cold brew kegs and nitrogen cylinders to give cafes the option of ambient air or nitrogen gas.

Doesn’t Oxygen Destroy Coffee’s Flavor?

The question Tata faces regularly is whether ambient air-brewed nitro cold brew can match the full and creamy mouthfeel of pure nitrogen-brewed nitro coffee. “We’ve run taste tests before, and customers can’t tell which drink is made with pure nitrogen and which is made with air. As long as they’re drinking it within a couple of hours, there’s no noticeable difference in flavor.”

He explains: “Most nitro coffees have about 40 parts per million (ppm) of nitrogen. That seems to be standard practice. We designed NitroBrew systems so that you can infuse your drink with a lot more nitrogen, up to 100 ppm. The idea that you need compressed nitrogen to get that particular mouthfeel doesn’t apply.

Pure, compressed nitrogen will always have a place in pre-packaged beverages, where exposure to oxygen over long periods will compromise the flavor quality. Cafes, however, can use ambient nitrogen to infuse drinks simply and with minimal waste.

“It always comes down to the customer experience,” Tata says. “And if there’s a way to create a great experience with less waste, that seems like a good idea.”

Visit NitroBrew’s website to learn more about their commercial nitro coffee systems.